We offer a wide range of precise and high quality complex solutions for printed materials

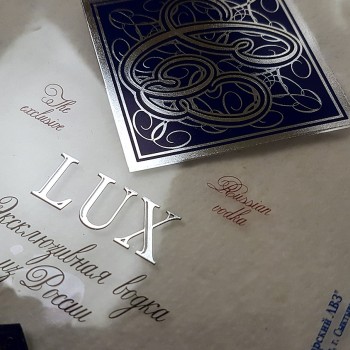

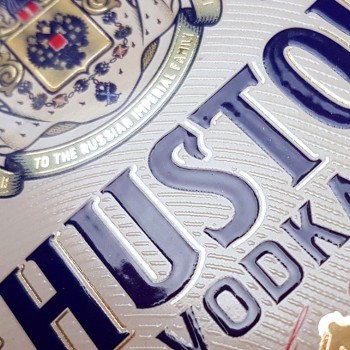

Cold foil printing

Cold foil printing is a technology for application of a metallic layer (foil) on the substrate to be overprinted afterwards. Flex print in combination with cold foil printing ads up to the visual presentation of the end product, giving a profound and precise reproduction of details, ensuring maximally dense ink coverage for transparent materials and small background transparency for printed areas, therewith enhancing the aesthetic look of the end product.

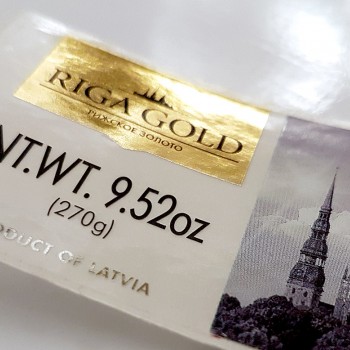

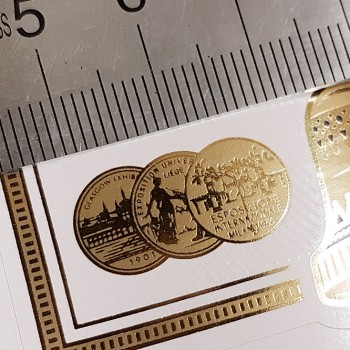

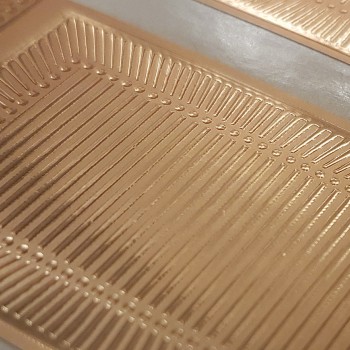

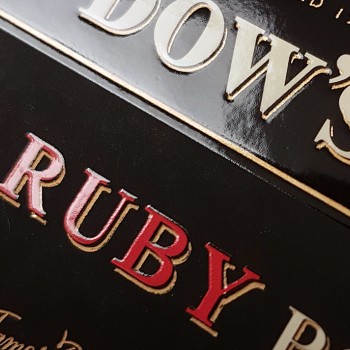

Hot foil stamping and embossing

Hot foil stamping is a process where metallic foil is pressed by a heated die into the surface of a material. We offer a wide range of foil colours, including gold, silver, blue, green and other. Foils are also available as matt, gloss and pearl foil variations.

Relief printing technique makes it possible to accentuate individual design elements or a particular area of the printed material by creating raised or recessed relief of an image or a combination of both, therewith achieving particular emphasis on separate elements of the printed material. A special added value effect may be achieved by combining relief printing with UV coating.

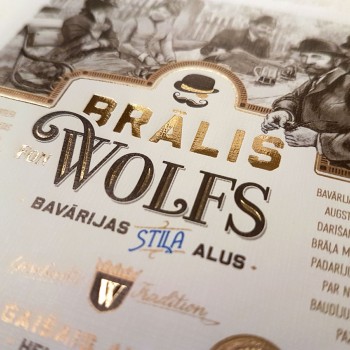

Silk screen printing and varnishing

We use an automatic screen printing press which accounts for fast and precise work process. This automatic solution is highly effective and perfectly tailored for after-production of high end product quantities. The printed end material is received in rolls and subsequently applied back to rolls already cut and sorted according to the customer’s needs.

Paper print finishing services

We offer the following paper print post-production (finishing) services: complex shape cutting, different folding options, creasing, gluing, page sorting, binding – saddle stitching, gluing with thermal glue, hard cover binding etc. We also offer lamination of printed items with gloss and matt finish, likewise varnishing with disperse or UV varnish and other print finish services, as requested by our customers.

Printing solutions

We offer gigh quality and innovative printing solutions for packaging